End-to-End Custom Swimwear Factory

Driven by efficient manufacturing and decades of industry expertise, ASGFashions ensures every stitch of your custom swimwear reflects perfection.

na indústria da moda

0

+ Anos

Fábrica Integrada

0

+ ㎡

Capacidade Mensal

0

+

Equipe Profissional

0

+

Quality-Driven Manufacturing Process

From material preparation to finishing, ensuring high-quality, durable, and visually appealing outfits.

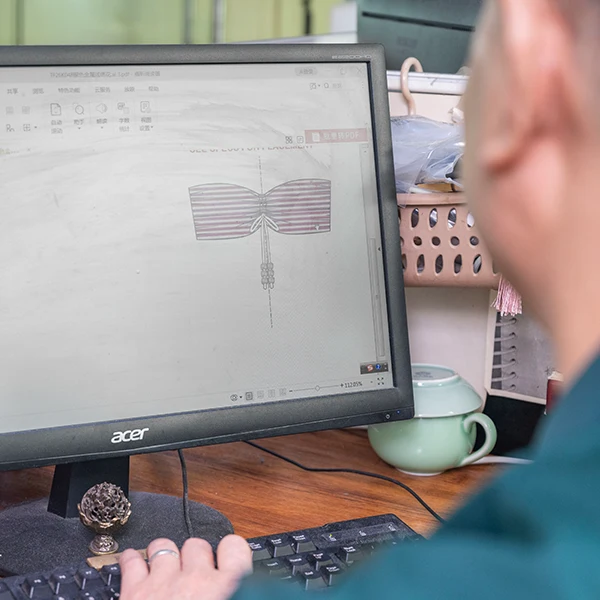

Step 1

Projeto & Development

Professional design teams collaborate to develop ergonomic, safe prototypes through sketches and paper prototypes.

Step 2

Fabric Sourcing

Source fabrics from approved suppliers, inspected for color, shrinkage, and durability.

Step 3

Precision Cutting

Computer-guided cutting optimizes fabric use and ensures precise dimensions.

Step 4

Sewing & Conjunto

Skilled operators sew and assemble components on 3 production lines, following quality standards.

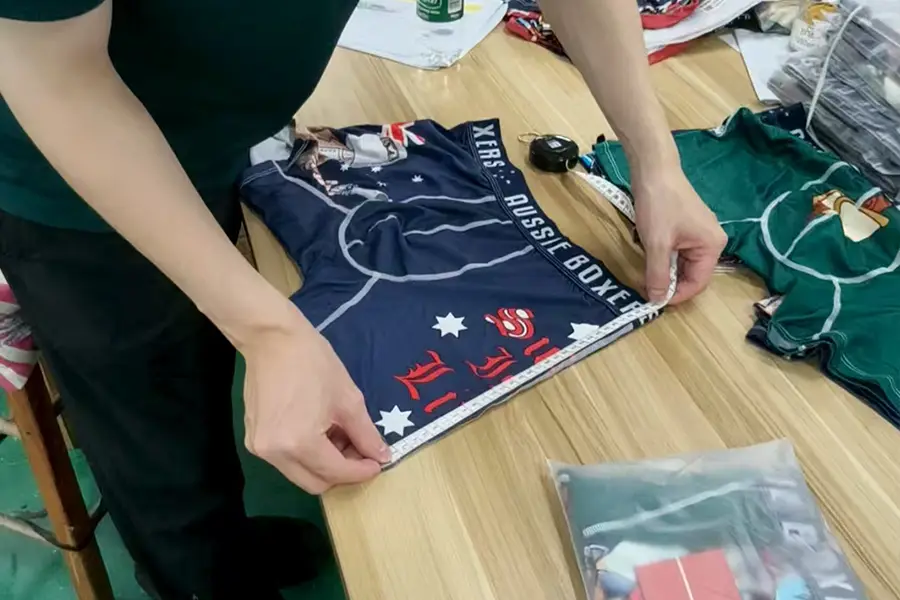

Step 5

Quality Control

Multi-stage inspections at key intervals to validate stitch density, seam integrity, and functionality.

Step 6

Embalagem & Entrega

Eco-friendly packaging with product labels, coordinated for timely global delivery.

Quality Control Process

From fabric sourcing to final packaging, we enforce meticulous inspections and scientific testing.

Raw Material Inspection

All fabrics, accessories, and trimmings undergo rigorous internal audits and third-party certifications including azo-free dye tests and tensile strength evaluations before production begins.

In-Process Inspections

Real-time quality checks at every production stage, with mid-line stitch audits, fabric defect scans, and compliance verification against safety and ergonomic standards.

Final Product Certification

Thorough examination of finished goods packaging for integrity, label accuracy, moisture resistance, and damage prevention prior to carton sealing and dispatch.