Asg Fashions compares leading yoga wear manufacturers against key operational standards, including certifications such as OEKO‑TEX® و طَوّق. By breaking down each supplier’s technical expertise, production capacity, and MOQ, Asg Fashions helps you choose a factory partner that is both scalable and financially sustainable for your yoga apparel line.

قمة 10 Private Label Yoga Leggings Manufacturers

Who each Manufacturer is best for

| Manufacturer | Location | Core Strength | Verdict |

|---|---|---|---|

| أزياء ASG | Dongguan, الصين (Global Shipping) | Private Label Yoga Leggings & Activewear | Best for startups needing a no-MOQ, factory-direct partner with zero inventory risk. |

| Bali Swim | Bali, Indonesia | Sustainable Swimwear & Activewear | Ideal for eco-conscious brands prioritizing ethical production and recycled fabrics. |

| Blue Associates Sportswear | United Kingdom | Technical & Performance Sportswear | A UK-based consultancy for established brands seeking end-to-end technical apparel development. |

| Gym Leggings USA | الولايات المتحدة الأمريكية | US-Made Gym & Fitness Apparel | The top choice for US-based brands wanting fast domestic shipping and “Made in the USA” quality. |

| Alanic Global | Beverly Hills, الولايات المتحدة الأمريكية (Global Offices) | Bulk Athletic & Team Sportswear | A large-scale global manufacturer for wholesalers and retailers requiring bulk orders. |

| Hingto Sportswear | الصين | Custom Yoga Wear & Fitness Apparel | Great for small and medium e-commerce brands looking for flexible MOQs and competitive pricing. |

| Zega Apparel | الولايات المتحدة الأمريكية (with overseas production) | Full-Service Custom Apparel | A versatile partner for startups needing low minimums and a wide range of clothing customization. |

| SGL Sports | الصين | أداء & Compression Wear | A specialized choice for brands demanding high-performance gear with technical fabrics. |

| Berunwear | الصين | Cycling, Yoga & Team Sportswear | An experienced one-stop solution for medium to large brands producing diverse sportswear lines. |

| Tokalon Clothing | الصين | Sustainable & Ethical Activewear | Perfect for wellness brands focused on using eco-friendly materials in their custom activewear. |

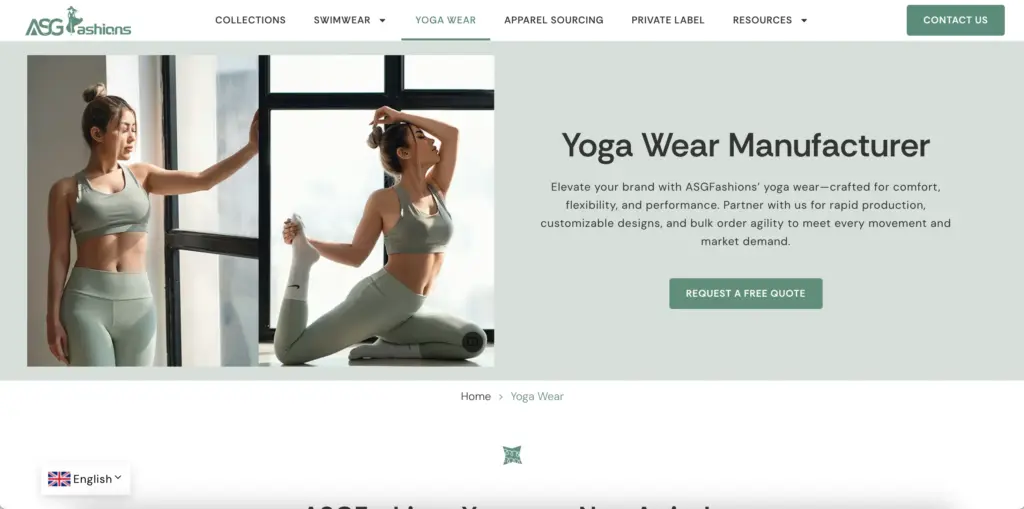

أزياء ASG

ASG Fashions is a factory‑direct manufacturer based in Dongguan, الصين, specializing in private label yoga leggings and activewear. If you run an e‑commerce brand, work as an influencer, or manage a boutique store, their model is built for you: flexible, low‑volume runs that make it easy to test new designs and markets without over‑ordering.

The core service is an end-to-end manufacturing solution that includes full OEM/ODM customization. They operate on a no-MOQ policy, which directly addresses the inventory risk common for new businesses. The sampling process is structured for speed, with a stated turnaround of 7-10 days to facilitate rapid product development.

📊 At a Glance:

- 📍 Location: Dongguan, الصين (Global Shipping)

- 🏭 Core Strength: Private Label Yoga Leggings, ملابس سباحة مخصصة, Activewear, Fashion Apparel

- 🌍 Key Markets: Startups & Influencers, E-commerce Brands, Boutique Retailers

Why We Picked Them:

| ✅ The Wins | ⚠️ Trade-offs |

|---|---|

|

|

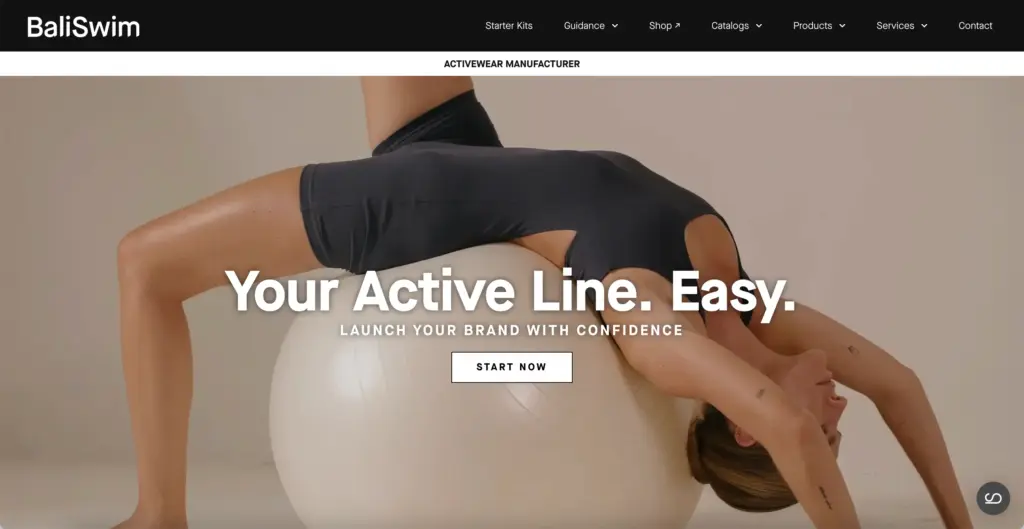

Bali Swim

Bali Swim is a specialized manufacturer based in Bali, Indonesia, with a clear focus on the swimwear and activewear markets. They primarily serve eco-conscious brands and boutique labels that require transparent and ethical supply chains, with a significant client base in the European market. Their operational model is built to accommodate clients who prioritize sustainability over lowest-cost production.

The factory’s core capability lies in its material sourcing and production standards. They provide access to a range of sustainable and recycled fabrics, which is a primary differentiator. Production lines are structured to meet verifiable ethical standards, addressing key concerns for brands building a reputation on responsible manufacturing. This specialization makes them a functional partner for apparel lines like swimwear and yoga leggings where material and production ethics are key selling points.

📊 At a Glance:

- 📍 Location: Bali, Indonesia

- 🏭 Core Strength: ملابس السباحة, Yoga Leggings, Activewear

- 🌍 Key Markets: Eco-conscious Brands, Boutique Labels, European Market

Why We Picked Them:

| ✅ The Wins | ⚠️ Trade-offs |

|---|---|

|

|

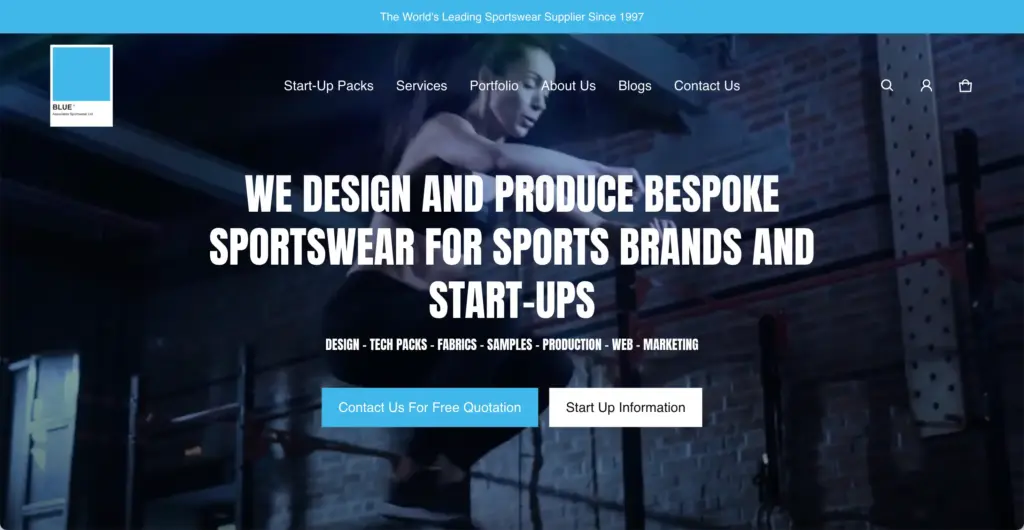

Blue Associates Sportswear

Blue Associates Sportswear operates as a design and manufacturing consultancy based in the United Kingdom. They specialize in end-to-end product development for technical sportswear and athleisure. Their focus is on serving established brands that require a managed process for performance-driven apparel collections, acting as an outsourced development partner.

The firm’s model covers the entire supply chain from initial concept and technical design through to material sourcing and production oversight. They function as a dedicated product development team, handling the complexities of creating specialized garments like performance leggings and technical outerwear. This structure is built to integrate with existing brand operations rather than simply supplying finished goods.

📊 At a Glance:

- 📍 Location: United Kingdom

- 🏭 Core Strength: Technical Sportswear, Performance Leggings, Outerwear

- 🌍 Key Markets: Established Sportswear Brands, Performance Apparel Market

Why We Picked Them:

| ✅ The Wins | ⚠️ Trade-offs |

|---|---|

|

|

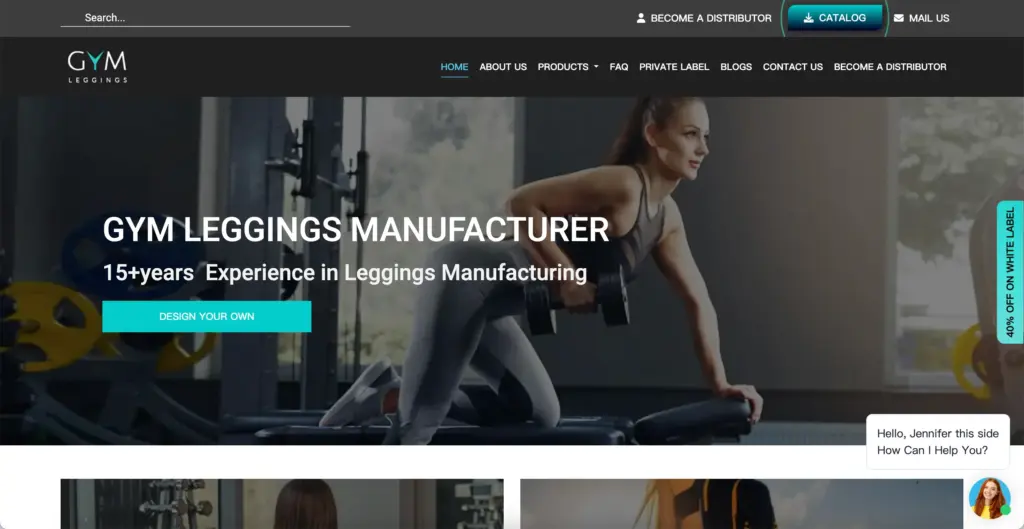

Gym Leggings USA

Gym Leggings USA operates as a domestic private label manufacturer of activewear. The company focuses exclusively on the US market, supplying gym leggings, حمالات الصدر الرياضية, and related fitness apparel to brands, gyms, and independent personal trainers seeking local production partners.

Their primary operational advantage is a localized supply chain that facilitates faster production turnaround compared to overseas alternatives. By manufacturing domestically, they enable clients to bypass international freight delays and customs clearance, though this model typically involves higher labor and material costs.

📊 At a Glance:

- 📍 Location: الولايات المتحدة الأمريكية

- 🏭 Core Strength: Gym Leggings, Sports Bras, Fitness Apparel

- 🌍 Key Markets: US-based Fitness Brands, Gyms, Personal Trainers

Why We Picked Them:

| ✅ The Wins | ⚠️ Trade-offs |

|---|---|

|

|

Alanic Global

Alanic Global operates as a large-scale international manufacturer and wholesaler, specializing in custom athletic apparel. Their market position is clearly defined, serving established wholesalers, large retail chains, and sports teams that require bulk production runs. They are not structured to service startups or low-volume orders, focusing instead on clients with significant distribution needs.

The company’s core capability lies in its extensive product catalog, which covers everything from technical yoga leggings to complete team sportswear kits. This breadth indicates a well-developed supply chain and diverse production lines. With a headquarters in Beverly Hills and a global office network, their infrastructure is built to manage complex international logistics and large-scale manufacturing programs.

📊 At a Glance:

- 📍 Location: Beverly Hills, الولايات المتحدة الأمريكية (Global Offices)

- 🏭 Core Strength: Yoga Leggings, Team Sportswear, General Activewear

- 🌍 Key Markets: Wholesalers, Large Retailers, Sports Teams

Why We Picked Them:

| ✅ The Wins | ⚠️ Trade-offs |

|---|---|

|

|

Hingto Sportswear

Hingto Sportswear operates as a specialized manufacturer in China, focusing on the custom activewear market. Their operational model is built to serve startups, e-commerce stores, and small to medium-sized brands—clients often underserved by larger factories with high volume requirements. The service scope covers the production lifecycle from design assistance and fabric sourcing to final private labeling.

The primary capability of Hingto is their flexible MOQ structure. This approach allows newer brands to launch products with lower initial capital investment and reduced inventory risk. By integrating services like material sourcing and design consultation, they streamline the supply chain for clients who may lack extensive production experience, consolidating multiple vendor interactions into a single point of contact.

📊 At a Glance:

- 📍 Location: الصين

- 🏭 Core Strength: ارتداء اليوغا, ملابس السباحة, Fitness Apparel

- 🌍 Key Markets: Startups, Small & Medium-Sized Brands, E-commerce Stores

Why We Picked Them:

| ✅ The Wins | ⚠️ Trade-offs |

|---|---|

|

|

Zega Apparel

Zega Apparel operates as a full-service private label manufacturer targeting startups, streetwear labels, and e-commerce brands. They provide a single point of contact for companies that require a broad range of custom apparel, including hoodies, t-shirts, and activewear like yoga leggings. Their model is built to support new market entrants by reducing typical manufacturing barriers.

The company’s core service consolidates multiple production processes, from initial cut-and-sew patterns to final decorations like printing and embroidery. While based in the USA for coordination, production is handled overseas. This structure allows them to offer extensive customization options and low minimum order quantities, reducing the initial capital required for new clothing lines.

📊 At a Glance:

- 📍 Location: الولايات المتحدة الأمريكية (with overseas production)

- 🏭 Core Strength: Custom Apparel, Hoodies, T-Shirts, Yoga Leggings

- 🌍 Key Markets: Startups, Streetwear Brands, التجارة الإلكترونية

Why We Picked Them:

| ✅ The Wins | ⚠️ Trade-offs |

|---|---|

|

|

SGL Sports

SGL Sports operates as a focused private label manufacturer of performance sportswear and activewear. Their production is centered on yoga leggings, compression gear, and other athletic apparel for brands that prioritize function and durability over fast-fashion trends. This specialization makes them a suitable partner for established performance brands and athletic organizations.

The company’s core operational strength lies in its work with technical fabrics. Their manufacturing processes are geared toward materials that offer specific functional benefits, such as moisture-wicking, compression, and four-way stretch. This capability is critical for producing reliable gear for fitness professionals and athletic teams who depend on the apparel’s performance during use.

📊 At a Glance:

- 📍 Location: الصين

- 🏭 Core Strength: Performance Yoga Leggings, Compression Wear, Sports Uniforms

- 🌍 Key Markets: Performance Brands, Athletic Teams, Fitness Professionals

Why We Picked Them:

| ✅ The Wins | ⚠️ Trade-offs |

|---|---|

|

|

Berunwear

Berunwear is a China-based OEM and ODM sportswear manufacturer. The company operates as a one-stop solution for global activewear brands, focusing on technical apparel categories like cycling wear, yoga garments, and team sportswear.

Their operational model covers the entire supply chain, from initial design consultation and material sourcing to full-scale production. This integrated process allows brands to consolidate manufacturing with a single partner, streamlining logistics for medium-to-large wholesale orders.

📊 At a Glance:

- 📍 Location: الصين

- 🏭 Core Strength: Cycling Wear, Yoga Apparel, Team Sportswear

- 🌍 Key Markets: Global Sportswear Brands, Wholesalers

Why We Picked Them:

| ✅ The Wins | ⚠️ Trade-offs |

|---|---|

|

|

Tokalon Clothing

Tokalon Clothing operates as a private label manufacturer based in China, focused specifically on the sustainable activewear sector. They serve eco-conscious startups and established wellness brands that require verifiable ethical production and the use of eco-friendly materials in their supply chain.

The company provides end-to-end production services, managing projects from initial design consultation through to final delivery. Their core operational strength lies in sourcing and working with specialized materials for custom yoga leggings, حمالات الصدر الرياضية, and other fitness apparel. This model is built for brands that lack their own in-house production teams.

📊 At a Glance:

- 📍 Location: الصين

- 🏭 Core Strength: Sustainable Activewear, Yoga Leggings, Sports Bras

- 🌍 Key Markets: Eco-conscious Startups, Established Wellness Brands

Why We Picked Them:

| ✅ The Wins | ⚠️ Trade-offs |

|---|---|

|

|

Comparison Table: Price vs. Speed vs. MOQ

Most private label manufacturers operate on a custom quote basis. MOQ is the clearest public differentiator, with options ranging from 50 to 200+ units.

Most private label manufacturers don’t publish flat rates or lead times. Pricing and speed are almost always tied to order volume, material choices, and design complexity, which requires a direct quote. MOQ is the most transparent metric, showing who caters to startups versus established brands.

| Manufacturer | Lead Time & Speed | MOQ & Production Flexibility | Pricing Models & Tiers |

|---|---|---|---|

| أزياء ASG | Direct Inquiry Required | Varies (Factory Intermediary) | Custom Quote |

| Bali Swim | Fast Sampling (ملابس السباحة) | 100 pieces | Custom Quote |

| Blue Associates Sportswear | Direct Inquiry Required | Flexible (Bespoke Focus) | Custom Quote (غالي) |

| Gym Leggings USA | Direct Inquiry Required | Low (Specifics Undisclosed) | Custom Quote |

| Alanic Global | Direct Inquiry Required | Flexible (Suited for Volume) | Wholesale (Volume-Based) |

| Hingto Sportswear | Direct Inquiry Required | 100-200 pieces | Custom Quote (Mid-High) |

| Zega Apparel | Direct Inquiry Required | 50 pieces | Custom Quote |

| SGL Sports | Direct Inquiry Required | 200 pieces | Competitive Wholesale |

| Berunwear | Direct Inquiry Required | 200 pieces (Negotiable) | Custom Quote |

| Tokalon Clothing | Direct Inquiry Required | 150 pieces | Custom Quote (Boutique) |

Launch Your Custom Yoga Wear Line, Starting from Just One Piece.

How to Choose the Best Manufacturer: 5 Key Metrics

Beyond price, vet partners on material quality, production capacity, ethical standards, and technical skill. These metrics separate reliable manufacturers from production liabilities.

1. Material Quality and Design Excellence

The fabric is the product. A manufacturer’s ability to source and work with high-performance materials is non-negotiable.

- Fabric Sourcing: Your partner must work with high-performance fabrics—polyester, polyamide, and quality natural blends. Anything less is a compromise.

- Sample Testing: Always test samples. Verify fabric weight, تمتد, color fastness, and durability yourself. Don’t take their word for it.

- Sizing Capability: Confirm they have proven experience with inclusive sizing, from XXS to plus sizes. Inconsistent grading is a common and costly failure point.

2. Production Capacity and MOQ

A mismatch in scale or financial terms will kill a partnership before it starts. Get clarity on production realities upfront.

- Scalability: Can they scale with you? A good partner for 100-unit runs might be a liability at 10,000 units. Plan for growth.

- MOQ Alignment: Their MOQ (per style and color) must align with your cash flow and business model. If it doesn’t, walk away.

- Timeline Transparency: Get firm production timelines for both small and large orders. Vague answers signal a disorganized operation.

3. Ethical Standards and Certifications

Ethical production is no longer optional; it’s a core component of brand reputation and risk management.

- Demand Proof: Don’t just ask about ethics. Verify their certifications, such as WRAP, بسي, ISO 9001, GOTS, or OEKO-TEX®.

- Credential Access: A legitimate partner will provide copies of credentials without hesitation. Any delay is a major red flag.

- Reputation Management: This isn’t just about compliance; it’s about protecting your brand. Cutting corners here will eventually cost you customers.

4. Multi-Stage Quality Control Process

A single, final QC check is worthless. True quality control is a process, not an event.

- Process, Not Event: A real QC process happens at multiple stages: raw materials, in-line production, and final inspection. Anything less is just for show.

- Specific Checks: Inspections must cover precise measurements, correct seam placement, and consistent fit across all sizes. A simple “visual check” isn’t quality control.

- Third-Party Verification: For large orders, hire your own third-party inspection service. Trust, but verify.

5. Customization Flexibility and Technical Expertise

Many factories can sew, but few have the technical expertise required for high-performance activewear.

- Activewear Specialization: Do they actually understand activewear? Confirm their experience with technical grading and fit testing for diverse body types.

- Complexity Test: Test their technical skill. Ask for examples of complex designs they’ve produced, like leggings with mesh panels or sports bras with intricate straps.

- Functional Details: Verify they can execute the small but critical functional features, like pockets with silicone grips, without compromising quality or durability.

Frequently Asked Questions

How do I find a manufacturer for my clothing brand?

You can find manufacturers through specialized wholesale sourcing platforms and industry directories. When you shortlist partners, pay attention to their MOQ, what product categories they actually specialize in, how much customization they offer, and where they are based.

Is it better to manufacture yoga leggings in the USA or China?

It depends on your priorities. China offers better cost-efficiency and a massive manufacturing scale. The USA provides faster turnaround times for the domestic market and closer proximity, but usually at a higher production cost.

How much does it cost to manufacture 100 طماق?

The cost to produce 100 leggings can range from approximately $300 to over $2,000. Pricing depends on fabric quality, design complexity, and customization. Budget-friendly options might cost $3–$8 per unit, while premium, fully custom leggings can run from $13 to $30 per unit.

Can I get a sample before placing a bulk order?

Yes, getting a sample before committing to a bulk order is a standard industry practice. Manufacturers create a pre-production sample for your approval to ensure the design, ملائم, and quality meet expectations. This process typically takes 7-12 business days.

Final Thoughts

The lowest per-unit price is a trap. Prioritize partners with verifiable QC and certifications, because a cheap factory costs more in returns and brand damage.

Stop researching and start testing. Order paid samples from your top two candidates this week. Physical quality, not promises, determines your best partner.